How we personalised your Inkerman Gifts.

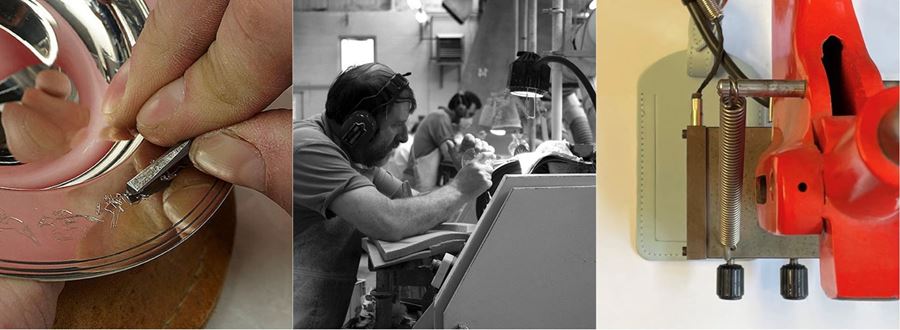

At Inkerman, we are famous for our range of personalised luxury gifts. Our skilled team of experts are on hand to make any purchase truly special by adding the personalisation of your choice.

Modern technology has moved on since ancient engraving methods and at one time, this skilled job used a variety of hand tools available, but technological advances have brought opportunities for far wider possibilities. Modern machinery might not have the same appeal as old-school hand crafted techniques, but it eliminates inconsistency, errors, mistakes and time taken which are crucial in the online ecommerce world.

So we’d wanted to share some of the techniques used that make a gift from Inkerman London so unique and handed on to the next generation. We still incorporate the ethos of skilled hand engraving, just using modern tools and technology.

Sandblasting

Sandblasting is used on all glass, wood and metal products in our sandblasting machine, This is a process where a stencil is placed on the tumbler, highball, champagne flute, wine glass, decanter, or jug, and a high-pressure stream of fine sand particles hits the surface and removes a layer of the glass to create a frosted or textured effect.

This technique enables us to add names, initials, monograms, messages, or any scene we have a bespoke stencil for, including our popular sports related theme or city scapes. Our wide range of etched glasses means that you will undoubtedly find something to suit any friend or family member for any special occasion, wedding, birthday, anniversary, Christmas or retirement present.

You can get some inspiration of our etched glassware in our Personalised Gift Gallery

Etching

Etching is used on metal, and modern techniques like laser engraving have replaced traditional methods with expert precision and accuracy based off a CAD drawing.

Laser etching uses a high-powered laser beam to create precise and permanent markings on the cleaned surface of the metal.

We upload a digital file into the laser etching machine containing the desired design, pattern, or text created using computer-aided design (CAD) software.

The laser etching machine is set up according to the material type, thickness, and desired depth of the etching. This includes adjusting the laser power, speed, and focus to achieve the desired results.

Once the machine is set up, the laser beam is emitted and directed onto the material's surface. The laser energy heats and vaporizes the material, creating a localized "burn" or "etch" mark. The laser moves along the predetermined path according to the design file, tracing the desired pattern or text onto the material.

We then cool the metal, remove any residue or debris, and clean, polish, or coat to enhance the appearance and protect the etched area.

Embossing

We use embossing techniques on our leather products. Embossing leather is a process of creating raised or depressed designs on the surface of leather by applying pressure and heat using a 3D metal die with the pattern, design or letters.

This die to then positioned, aligned and centred over the heated leather, and applied with pressure using a press. Once cooled, the embossed design is imbedded and is cleaned and smoothed to give a final product ready for your gifting.